First Class Tips About How To Check Back Pressure

Artificial lifting is one way of overcoming the effects of backpressure in depleted wells.

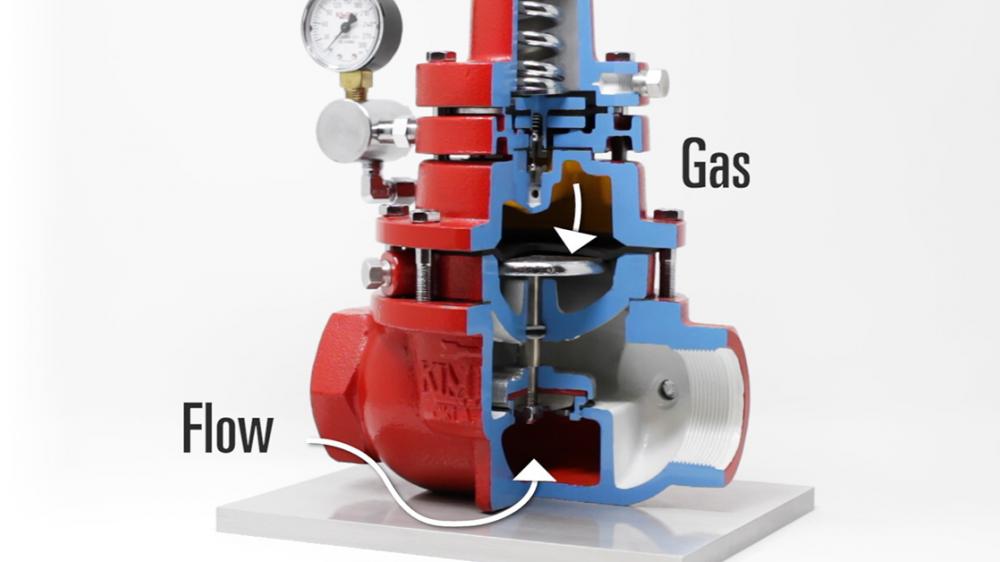

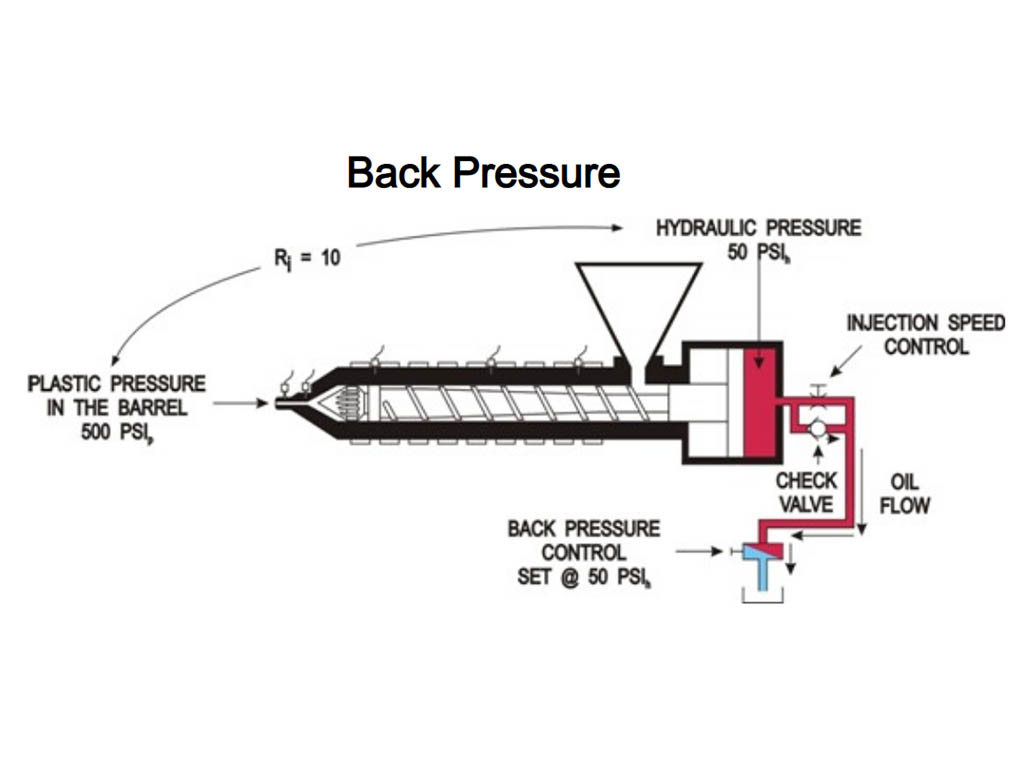

How to check back pressure. Another way to check for a backpressure problem is to check intake vacuum at the engine. Back pressure needs to be accounted for when sizing a prv. Such wells need a back pressure as a pressure check to control surges.

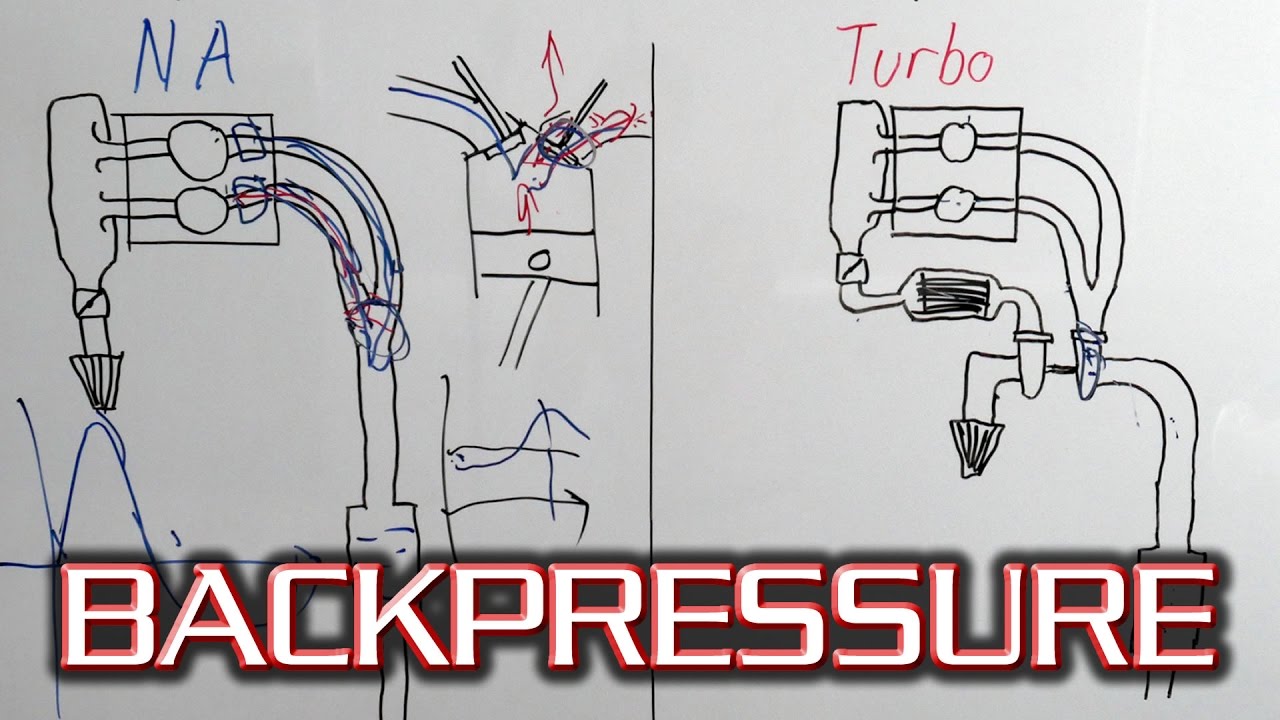

If you wanted to find the back pressure being caused by the catalytic converter, you simply plumb in the fitting before the cat, do a wot run and find the peak pressure. It's much easier to hook up a vacuum gauge to a vacuum hose or port than it is to remove an o2. How to check back pressure in diesel engine?

Open notepad and open the. On older engines with air injection or. In exchange, be it exchange 2010, exchange 2013 or exchange 2016, you might have come across back pressure alerts or where exchange just won't function.

Tap into the injection manifolds. Because back pressure is reported by a transport server in the application event log it is possible to automate checking for the events using powershell. You can also connect a hose fitting to your pressure gauge if there is a loss of pressure from the oxygen sensor located in the.

How much back pressure is acceptable? Back pressure is a feature of the microsoft exchange transport service to monitor the system resource. You can do this in several ways.

In general, back pressure should not exceed 10% of the set pressure,. Drill a 1/4 hole about 1 inside your head pipe where your aftermarket exhaust slip on. Come along with eric o at the sma shop as he has a look at this 2002 buick regal with a supercharged 3.8 that he just put an engine in and then discovered on.